NOE-Schaltechnik

Manufacturing formwork since 1957

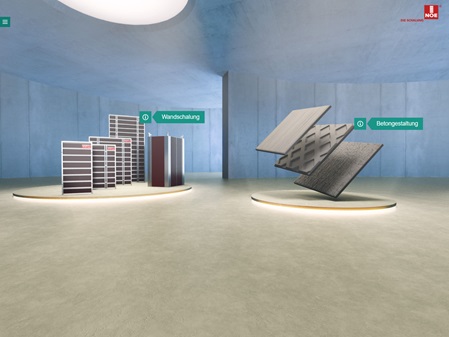

NOE-Schaltechnik formwork is used on large construction sites such as the Maracana Stadium in Rio de Janeiro, the Einhorn Tunnel in Schwäbisch Gmünd and the Milaneo shopping mall in Stuttgart. The company’s input often remains hidden from view in, for example, the foundations, where it gives structure and form. NOE-Schaltechnik’s formwork ensures the concrete can be poured to create exactly the right shape, in the right place and is of the highest quality. The multi-use steel formwork panels developed by Georg Meyer-Keller in the 1950s enabled the construction industry to complete projects quicker, cheaper, while conserving the earth’s natural resources.

Let us show you what we can do

Lower Saxony’s largest on-going coastal protection project

New canal lock in Otterndorf Saxony

The old Hadelner Canal lock is replaced by a new, modern and larger structure with the aim of improving coastal protection, land drainage and passage for shipping.

Careers at NOE

Keep in touch!

Find out about interesting topics at NOE.